Description

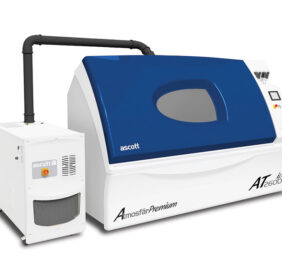

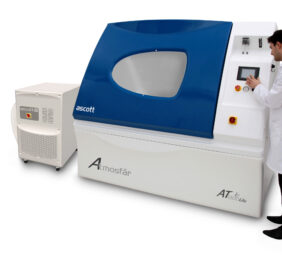

Ascott Analytical Cyclic Corrosion Test chambers

Key Features

Five model sizes:

- 450 Ltr (15.8 cu ft)

- 1000 Ltr (35.3 cu ft)

- 1300 Ltr (45.9 cu ft)

- 2000 Ltr (70.6 cu ft)

- 2600 Ltr (91.8 cu ft)

Extensive optional testing facilities:

Extensive range optional testing facilities, such as refrigeration and liquid immersion.

All Ascott Cyclic Corrosion Test chambers feature:

- Touch-screen, full color user control interface, employing the latest version of our highly intuitive operating software, for ease of programming and use.

- The operating software has a very large capacity for the creation of complex multi-step test programmes, so that the widest possible range of test profiles can be accommodated.

- The icon based control interface offers a variety of languages built-in for ease of understanding and use.

- RJ45 communications port enabling the chamber to be wired or wirelessly connected to a local area network (LAN) for logging and remote programming via a computer running optional software.

- A real-time, user configurable ‘clock’ to enable different test samples to be batched and have their exposure time monitored separately, with alarms to warn when a pre-set test period has been completed.

- Touch-screen operator control interface.

- ‘Easy Open’ pneumatically operated canopy.

- Dry seal gasket prevents wetting operator’s clothes, etc.

- Low loading threshold for loading and unloading.

- Large capacity salt solution reservoir mounted on castors for mobility.

- Calibration certificate.

- Canopy color choice.

- Set of sample racks.

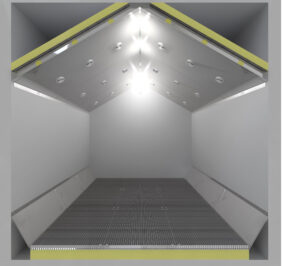

- Interior viewing window.

- Consumables spares kit.

- Easily accessible salt spray atomizer(s) in transparent hard-wearing acrylic.

- Purge of the cabinet interior with fresh air after testing and before the chamber is opened.

Modes of Operation

Ascott CCT chambers are designed to be flexible enough to comply with as many different CCT specifications as possible. As standard they come with the ability to create 4 distinct climates:

- Salt spray

- Condensation humidity (wetting)

- Air drying

- Controlled humidity

– which may be programmed to occur in any sequence and be repeated automatically. By choosing from a wide range of optional accessories, these climates may be added to as required to further extend the number of climates and conditions that can be created.

Specifications

|

||||||

| Cyclic corrosion test chambers | CC450ip | CC1000ip | CC2000ip | |||

| Chamber Capacity | 450 Ltrs/ 15.8cu ft |

1000 Ltrs/ 35.3cu ft |

2000 Ltrs/ 70.6cu ft |

|||

| Mounting Format | Floor standing | Floor standing | Floor standing | |||

| Loading threshold | 800mm/31.5″ | 800mm/31.5″ | 800mm/31.5″ | |||

| Chamber external dims, max | W | 1660mm/65.4″ | 2025mm/80.0″ | 2885mm/113.6″ | ||

| D | 840mm/33.1″ | 1205mm/47.5″ | 1205mm/47.5″ | |||

| H | 1510mm/59.5″ | 1720mm/67.5″ | 1720mm/67.5″ | |||

| Chamber internal dims, max | W | 1010mm/39.5″ | 1350mm/51.0″ | 2160mm/85.0″ | ||

| D | 640mm/25.0″ | 980mm/38.5″ | 980mm/38.5″ | |||

| H | 1140mm/45.0″ | 1320mm/52.0″ | 1320mm/52.0″ | |||

| Salt solution reservoir ext. dims. | W | 460mm/18.1″ | 560mm/22.0″ | 560mm/22.0″ | ||

| D | 620mm/24.5″ | 620mm/24.5″ | 620mm/24.5″ | |||

| H | 675mm/26.6″ | 675mm/26.6″ | 675mm/26.6″ | |||

| Salt solution reservoir capacity for extra capacity, see optional accessory ACC02 | 80 Ltrs/ 21 USgal |

115 Ltrs/ 30.4 USgal |

115 Ltrs/ 30.5 USgal |

|||

| Removable slotted sample racks see also optional accessories ACC17/ACC18) |

6 racks each with 28 angled slots |

8 racks each with 46 angled slots | 16 racks each with 46 angled slots | |||

| Chamber construction | Glass reinforced plastic, Polypropylene & PVC parts | |||||

| Color | 9 standard colours to choose from | |||||

| Temperature range | Adjustable from ambient to +50°C/+122°F | |||||

| Salt spray fall-out rates | Adjustable from 0.5 to 3.0 ml per 80 cm² per hour | |||||

| Electricity supply | 3 phase | 3 phase | 3 phase | |||

| Voltage (VAC) and frequency (Hz) dependant on country/region of installation | ||||||

| Water | Deionized/distilled for topping up air saturator and making salt solution. Air saturator requires a continuous water connection 0.5-6.0 bar (7.3-87 psi). If air saturator is topped up manually option ACC66 must be ordered | |||||

| Air | Clean dry & oil free, 4.0 to 6.0 bar (58-87psi) with 240 Ltrs (8.5cu.ft) per minute flow | |||||

| Exhaust | 3m (10ft) exhaust pipe is provided which should be terminated outside building | |||||

| Drain | 3m (10ft) drain pipe provided which should be terminated into floor level drain | |||||

| Operating environment conditions | +18 to +23°C (+64 to 73°F), 85% max RH (non condensing) ambient | |||||

Accessories

All Ascott test chambers are supplied complete and ready to run. Optional accessories may not therefore be necessary, but some may be considered desirable.

Use the link below to see the Ascott Accessories for salt spray chambers:

Ascott Salt Spray Chamber Accessories