Beskrivning

Drop Shape Analyzer – DSA Inkjet

Watching out for precision printing

High quality inkjet printing makes the perfect interplay between printing head control and

the ink indispensable. We have developed the Drop Shape Analyzer – DSA Inkjet to support

you in reaching this goal. Bringing along its own printing electronics, the instrument

incorporates intuitive tools for setting printing parameters and a highly innovative optical

system for analyzing the resulting jet stream of ink droplets. Parameters such as waveform

and frequency can be easily adjusted while observing the drops’ behavior live and analyzing

it automatically. With this direct approach, the DSA Inkjet helps you in optimizing your ink

formulations as well as the printing process.

Intuitive and safe printing head control

The easy-to-use wave form editor of the ADVANCE software realistically simulates electronic control in a real printing process. By storing the technical properties and limits of the printing head in ADVANCE, it is absolutely safe to test parameters in the whole performance range of the head without overstraining it.

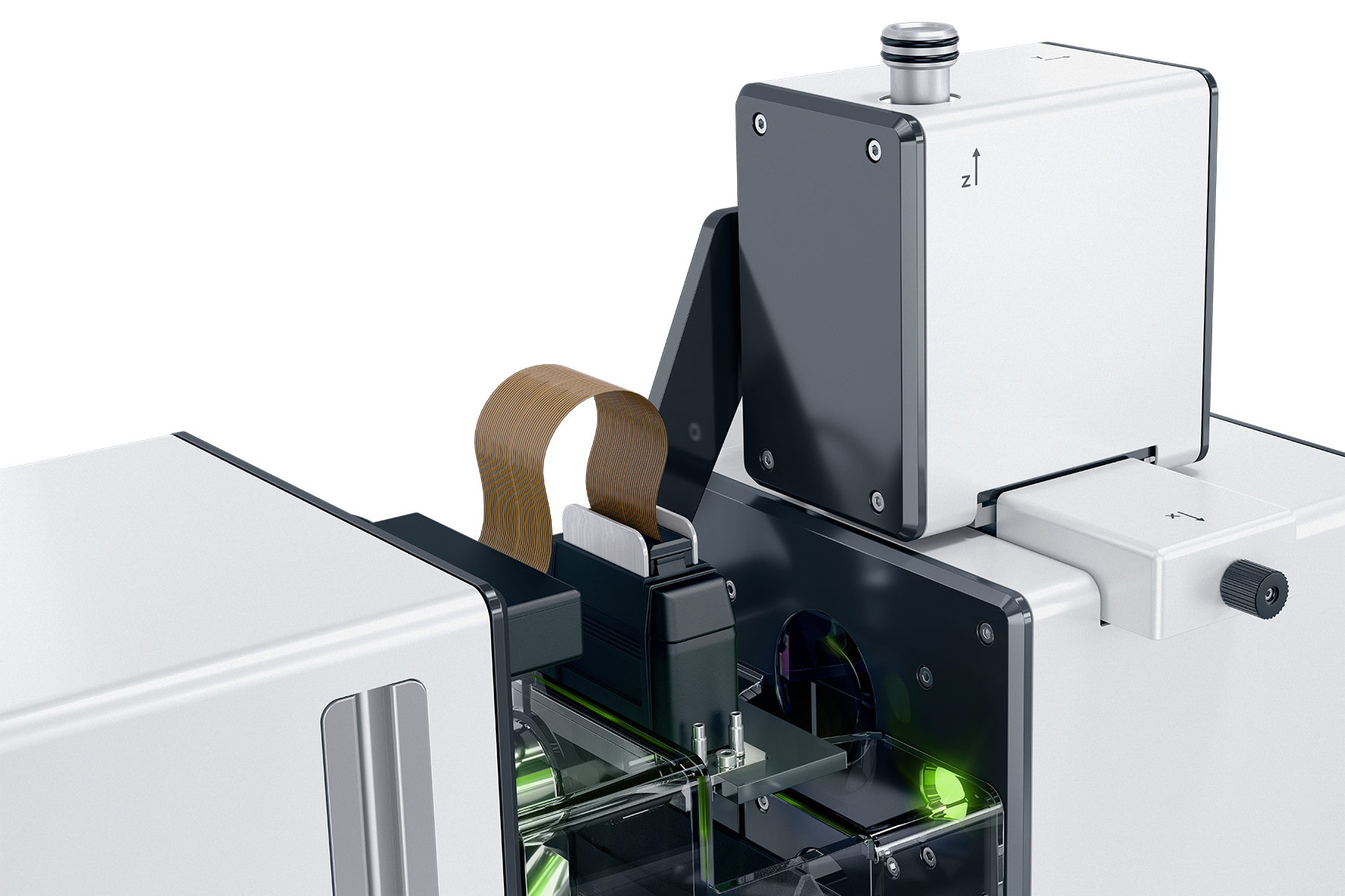

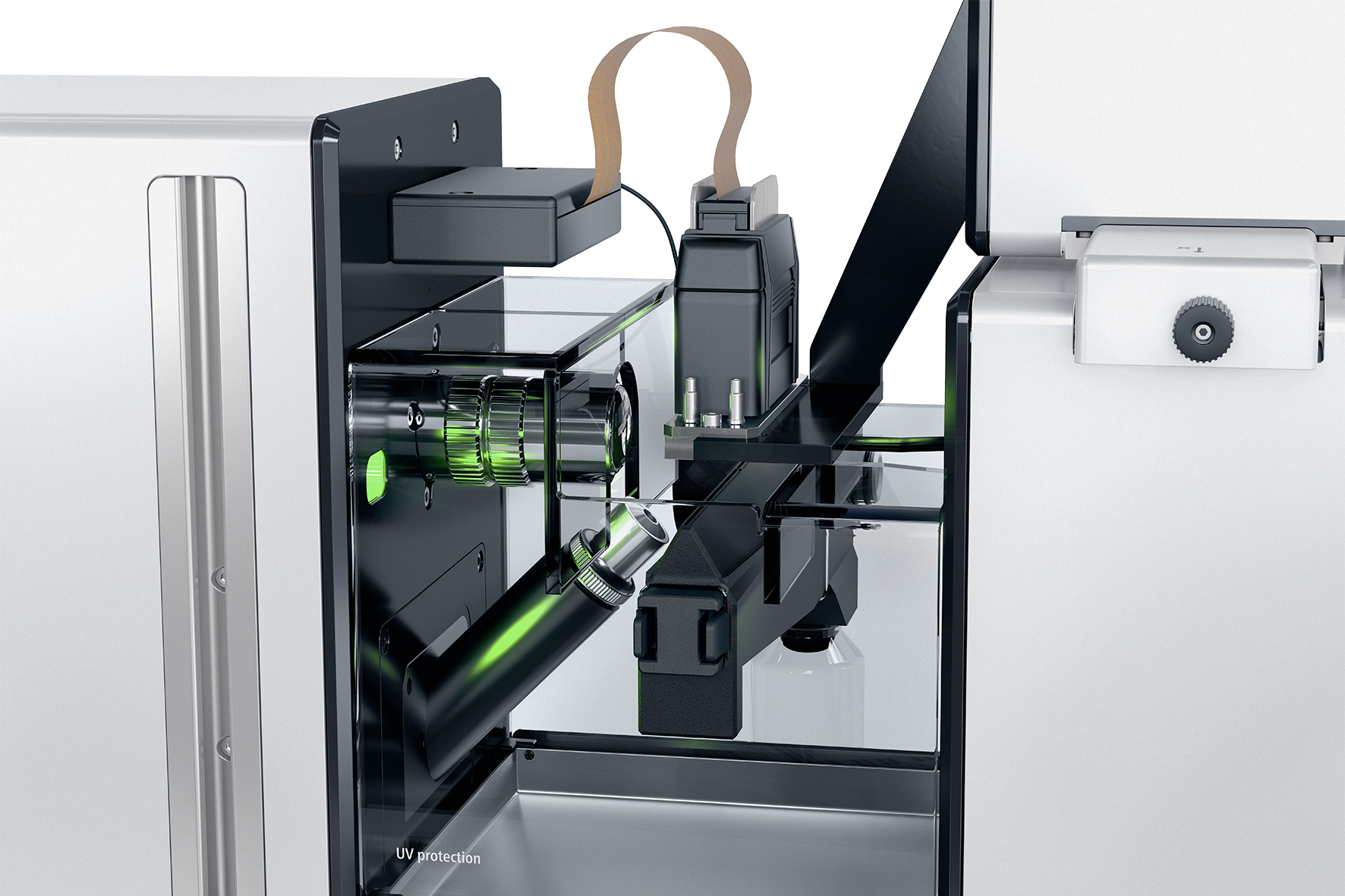

Innovative optical setup for imaging and analyzing drops

High-quality microscope optics focus on the jet of drops and delivers a clear video image. The DSA Inkjet uses an imaginative method to precisely analyze ink drops of just a few pico-liters at flight speeds of up to 40 m/s: Two different-colored light flashes in quick succession double-expose the drop in one and the same video frame of a color camera. By separating the color channels, discrete images of the same drop are obtained at intervals of a few microseconds. This opens up unprecedented opportunities of recognizing and analyzing drops automatically, providing a vast number of instructive result parameters:

- Speed of the drop

- Drop volume

- Trajectory (deviation from the perpendicular)

- Ligament length

- Number of satellite drops

By receiving these results as a quick feedback to the print parameter settings, they can be used to test a particular ink or to optimize the printing process. Moreover, with easy-to-create automation programs of the ADVANCE software, measurements can be carried out at controlled conditions with maximum repeatability for standardized tests of ink formulations.

Nozzle observation and automated image scale determination

Wetting the print head during printing can deflect the drop jet and clog the nozzles by drying out. To make unwanted ink drops visible at the nozzle rows, separate optics and illumination as well as a second camera provide a video image of the nozzles from below.

Another innovative development makes it easier to measure real drop dimensions such as volume or ligament length.The image scale is automatically determined with the aid of a calibration grid regularly projected into the camera image. This eliminates the need for image calibration when changing the zoom, saving time and ensuring reliable results.

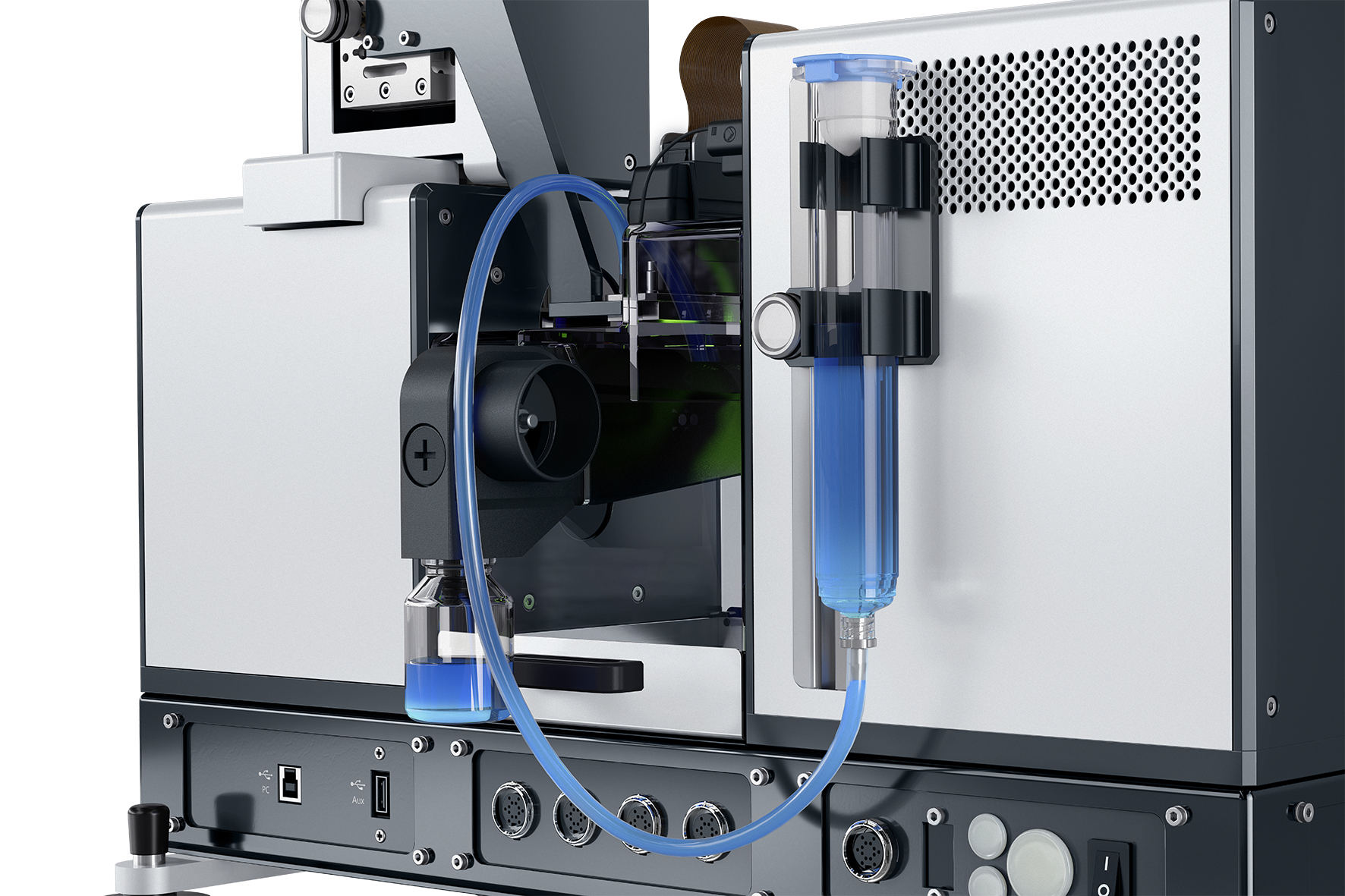

Thoughtful setup for practical suitability

The hardware components of the DSA Inkjet provide for safe and versatile use. Inserting the printing head and focusing on single nozzles is carried out in a few easy steps thanks to the three-dimensional fine-positioning system. The instrument is also equipped with a storage tank to supply the print head with ink during long-term measurements, whereby the drops are collected in a waste container. A suction device prevents harmful vapors. Thanks to a UV protection cover, UV-curing inks such as those used for 3D printing can also be examined.

Measurement options

- Setting waveform and frequency and watching the resulting drop behavior live

- Automated image analysis providing results such as volume, speed, trajectory, ligament length, and number of droplet parts

- Parallel video observation of the nozzles from below

- Fully automated image scale determination

- Long-term measurements and analysis of UV-curing inks