Optimizing Surface Coating Durability with Precision

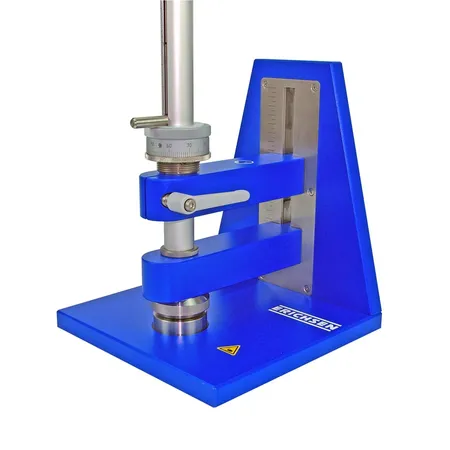

In the rigorous conditions of real-world applications, surface coatings are consistently subjected to impacts that can compromise their integrity, adherence, and overall durability. The ERICHSEN Impact Tester Model 304 provides a sophisticated solution for accurately assessing the resistance, deformability, and ductility of coatings and substrates against such stresses. Utilizing a ball impact test mechanism, this device simulates standard conditions to evaluate the performance of coatings, offering critical insights into their durability and protective capabilities. Designed for versatility, the Model 304 features adjustments for different specimen thicknesses and employs a precision-guided weight drop, equipped with either a ball head or male tappet, to deliver consistent and repeatable impact tests.

The Impact Tester Model 304 stands out in its ability to conduct both qualitative and quantitative assessments. With options for concave or convex deformation testing and adjustable impact energies, the tester enables comprehensive analysis of coating behaviors under stress. This facilitates not merely a pass/fail evaluation but an in-depth exploration of the minimum energy thresholds necessary to induce damage, thereby offering a nuanced understanding of material resilience.

Employing the ERICHSEN Model 304 assures adherence to international standards, including ISO, ASTM, DIN, NF, and SNV, enabling global application and compliance. Its versatility and precision make it an indispensable asset in the development and quality control of surface coatings across industries.