Optimized Performance for Advanced Adhesion Testing

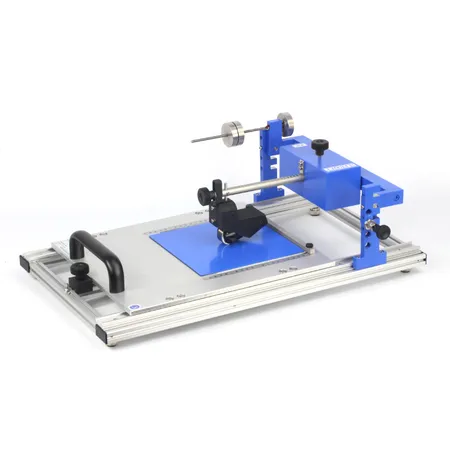

The SledCutter 295 XVII stands as a pinnacle of precision in manual cross-cut adhesion tests for coated panels, effectively overcoming the limitations of traditional hand-held tools. This tabletop device enables the application of defined cross-cut patterns with an outstanding accuracy thanks to its adjustable cutting force, linear guided cutting movement, and fixed path limitation. These features assure consistent grid cutting patterns at a precise 90° angle, facilitating the comparative testing of large series without user fatigue or injury risk.

Innovative Design Meets Functionality

Equipped with a linear guide for smooth carriage movement, and a height-adjustable load arm, the SledCutter 295 XVII simplifies the application of cross-cut patterns. It comes with a multi-cut adapter and a cutting tool that boasts six cutting edges, offering options for three different cutting distances to suit various testing needs. The scribing force is easily adjustable, securing a range from 2 to 40 N, extendable up to 60 N with an additional load weight, ensuring precise control over the cutting process.

Reliable Adhesion Testing Method

This device leverages the well-established cross-cut test method to evaluate the adhesive strength of paints and coatings, offering a direct insight into the material’s resistance to corrosion where the coating integrity is compromised. The SledCutter 295 XVII facilitates this testing method by allowing for controlled, consistent application of the cutting process, thereby providing reliable, visually assessable results that comply with EN ISO 2409 standards.