Individually Configurable Process Systems

Scilicent’s electroplating process systems offer versatile and individually configurable solutions for various plating applications. These comprehensive systems are designed to meet specific requirements across different industries.

Application Examples

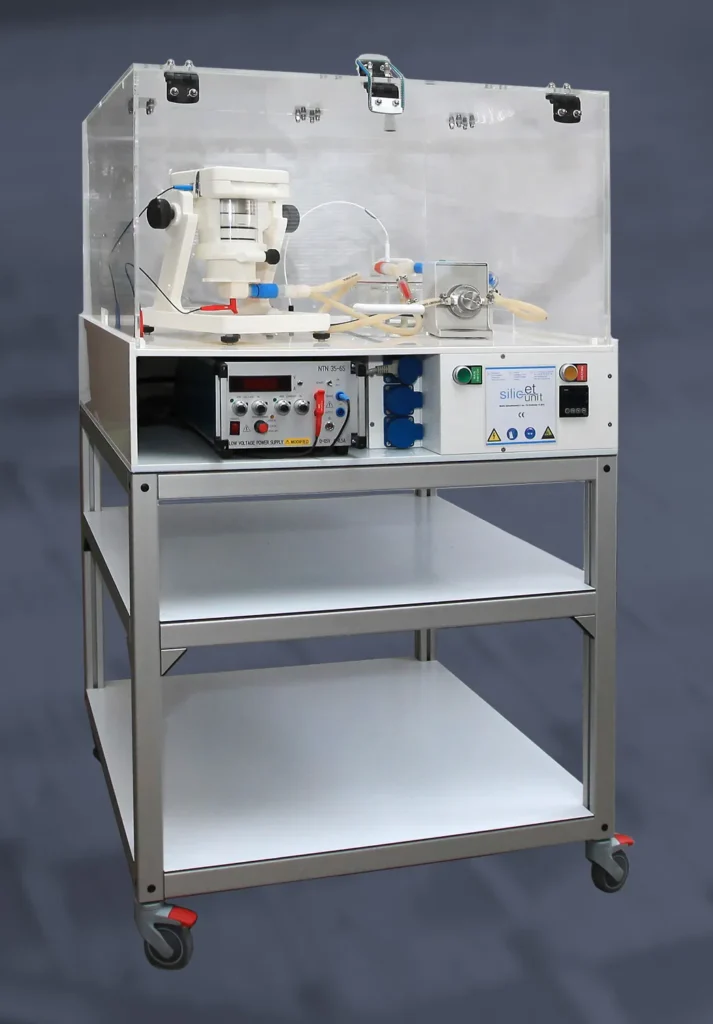

Our process systems include various configurations such as 4 inch and 12 inch plating systems, complete with units, tanks, temperature control systems, current supply, and mobile carts. The systems can be installed in exhaust chambers for acid copper plating applications and come with safety cabinets for enhanced operational safety.

System Components

Each system can include pumps, tanks, magnetic stirrers with heating, temperature control, current supply and mobile stations. The modular design allows for customization based on specific application requirements and facility constraints.