Advanced Wafer Processing Solutions

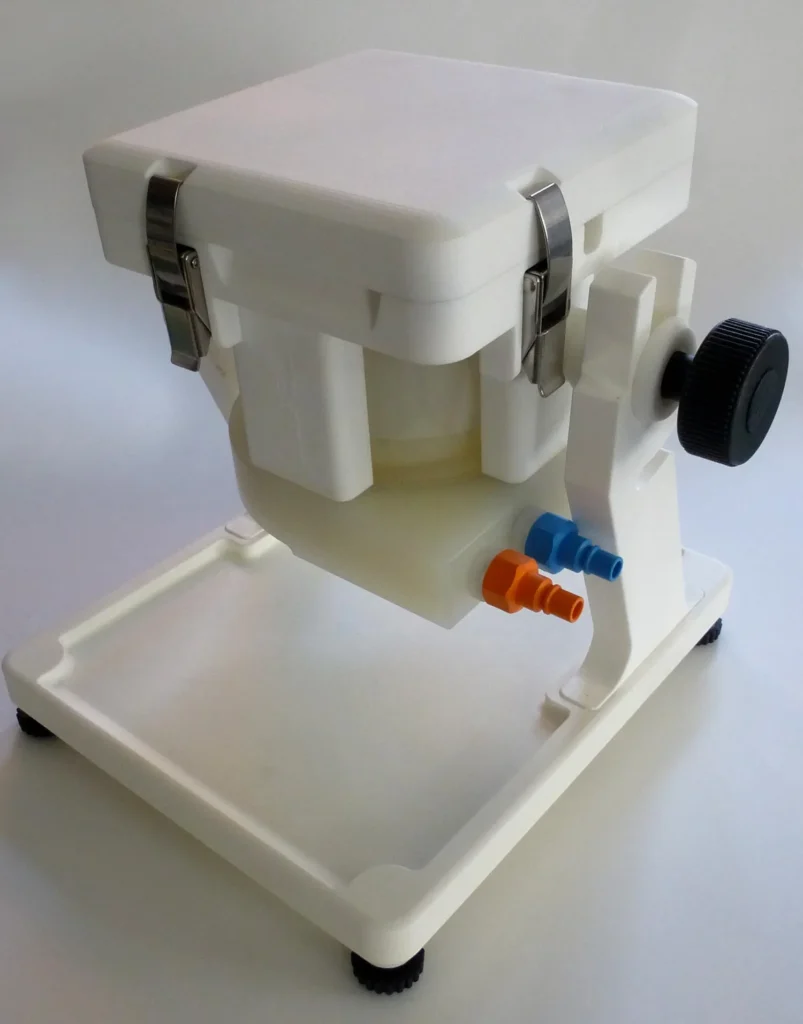

Silicet’s Electroplating Units deliver precision wafer processing capabilities for both single wafer and batch operations. These versatile units are designed for electroplating applications across various substrate formats, providing reliable and efficient processing from 2″ to 12″ wafers.

Flexible Processing Capabilities

The units support single wafer processing from 2″ – 12″ and batch processing from 2″ – 6″. Other substrate formats within the scope of these sizes are also accommodated, making the system highly adaptable to different production requirements.

Variable Parameters and Control

Each unit features adjustable distance between cathode and anode, with all types of anodes available on request. Flow control is adjustable from 0.5 – 5 l/min, offering both free flow and controlled flow options using a flow plate with defined layout. Temperature control ensures optimal processing conditions for consistent results.

Modular Design Benefits

The modular setup allows for easy disassembly and cleaning, with plating process exchange possible within minutes. This customer-friendly design enables quick replacement of all components, ensuring minimal downtime and maximum productivity.

Environmental and Cost Efficiency

The units minimize electrolyte volume, making them resource efficient, less harmful to the environment, and cost-saving. The inert gas atmosphere and air release system provide additional process control options for specialized applications.