Optimize Your Production Quality with GLOSSMASTER ONLINE 507

Ensuring consistent and uniform surface quality is paramount in today’s production and manufacturing sectors, spanning materials such as papers, plastics, metals, and woods. Fluctuations in gloss can significantly impact product acceptance, leading to higher quality control demands and potential rejections. The GLOSSMASTER ONLINE 507 plays a crucial role in providing a seamless, objective assessment of glossiness, catering to the rigorous quality expectations of modern customers.

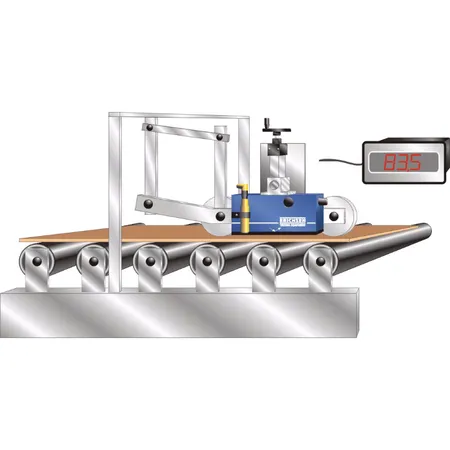

Seamless Integration into Production Lines

The GLOSSMASTER ONLINE 507 system is designed for direct installation on production lines, especially after UV drying processes. It offers real-time, non-contact gloss measurements, thereby controlling the quantity of coating applied and ensuring each batch meets your gloss standards. Automatic calibration and adjustable gloss measurement geometries (20° and 60°) simplify the integration into various manufacturing operations.

Advantages and Applications

Implementing the GLOSSMASTER ONLINE 507 eliminates the need for manual sample testing, significantly reducing potential rework and material costs associated with faulty batches. Whether it’s in a factory producing laminated parquet or a galvanizing plant adjusting pickling times, this system offers substantial savings and process optimizations. An external alarm feature ensures immediate notifications when gloss values exceed predefined limits, protecting against unexpected quality deviations.

Technical Highlights

Featuring non-contact, continuous operation, and the option for automatic calibration, the GLOSSMASTER ONLINE 507 stands out for its efficiency and reliability. Its advanced sensor technology combined with the flexibility in measurement angles makes it a versatile solution for various industrial applications.