Overview

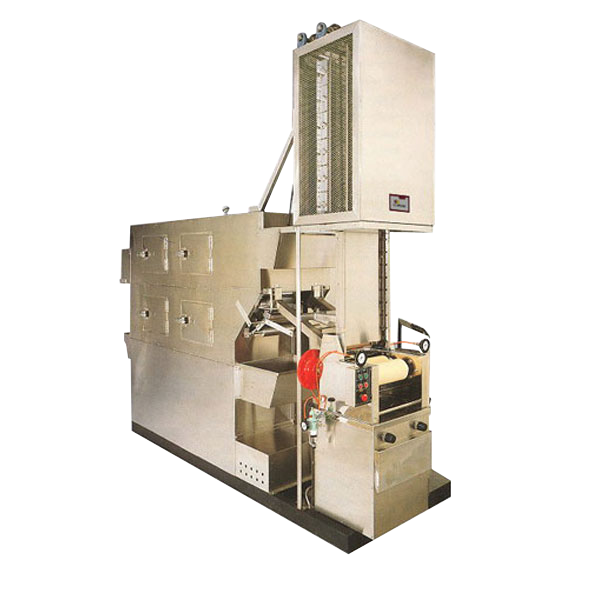

The Pad-Thermosol Range (Model PT-J) from SDL Atlas is an innovative textile testing solution designed for thorough and accurate fabric analysis. This equipment features a seamless integration of padding, infrared heating, and thermosoling processes to ensure precision and reliability in fabric testing.

Key Features

Equipped with a horizontal pneumatic-type padder, the Pad-Thermosol Range secures the test fabric on both ends using special clip bars. These are mounted on endless chains that facilitate continuous operation through the machine. Fabrics undergo a meticulous testing process, starting with an infrared pre-heater, moving through an intermediate dryer, and finally, the thermosoling zone. Post-testing, fabrics are automatically removed and collected into a reserve box, streamlining the testing process.

Advanced Testing Capabilities

With a roller width of 300 mm and a diameter of 125 mm, alongside a dyestuff trough with a capacity of approximately 100 cc – the Pad-Thermosol Range is engineered for efficiency and accuracy. This system provides a comprehensive solution for textile manufacturers, researchers, and quality control labs seeking reliable testing outcomes.