Description

DryRate 201

Precision Drying Rate Measurement Made Simple

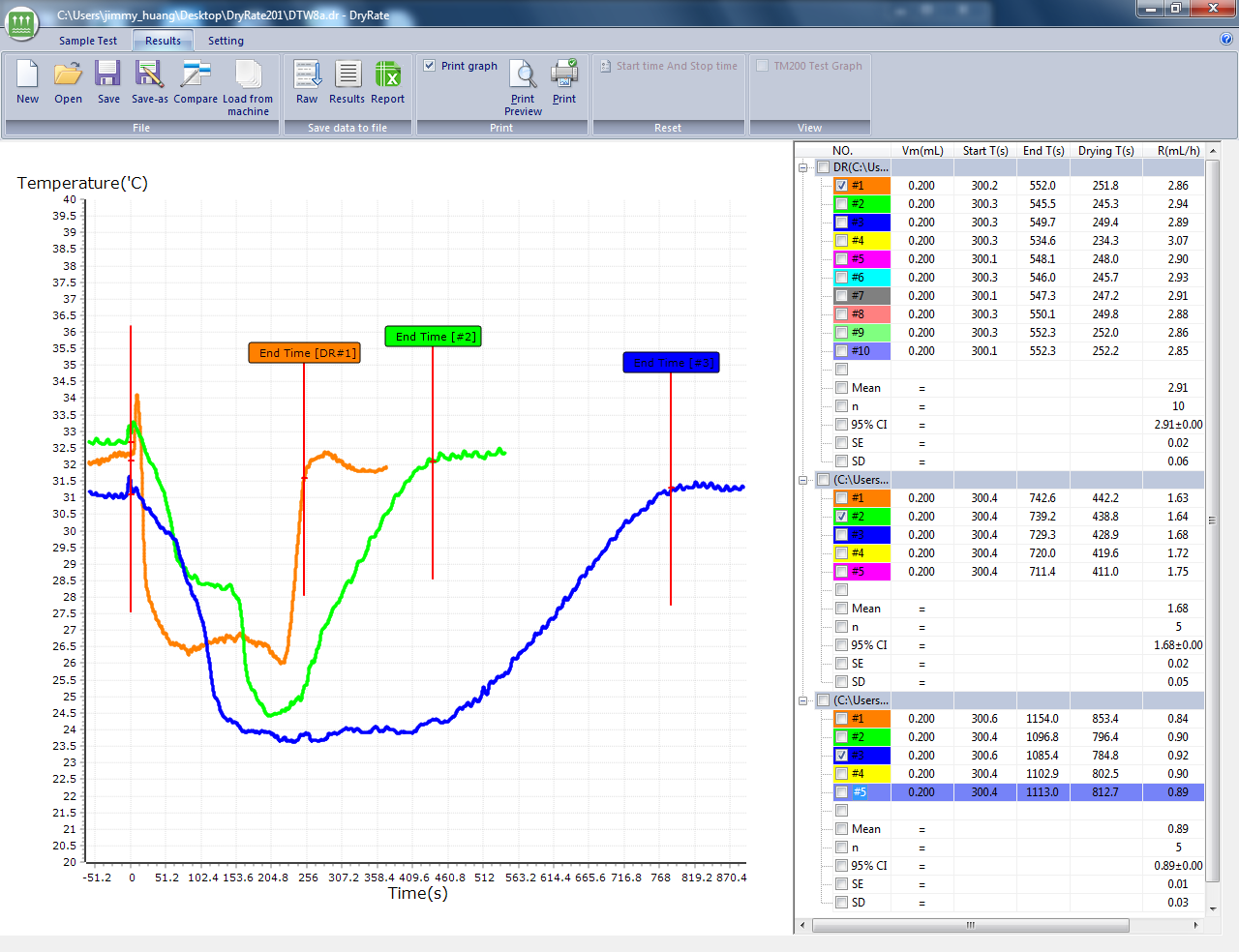

The popularity of moisture management products aimed at making the wearer feel dry and comfortable is soaring. State-ofthe-art measurement

and analysis of the drying characteristics of fabrics in the textile sector is essential. DryRate 201 is a fully automated and advanced instrument

with a heated metal plate, which simulates human skin starting to perspire at 37°C, that determines the drying rate based on evaporation rate from

the fabric. The instrument comes with a touch screen controller for setting parameters, monitoring testing status, and reading final results.

For more detailed analysis, testing data can be transmitted to a computer for real-time test curve display.

Testing Principle

Based on the principle of a wetted fabric against a heat source with air flow,

the evaporation of water will remove heat to reduce the surface temperature.

Detecting the temperature of the fabric surface accurately determines

whether the textile has become completely dry.

For the fully automated testing mode, the operator simply places the sample

in the test area, and the instrument will automatically run the test including

water dispensing and generate the results once completed. The operator can

change the amount of water and air flow through the testing parameters.

The manual test mode allows for the same change of air flow through the test

settings with the added ability to perform manual water dosing as described

in the AATCC 201 Test Method.

All test results are included in test reports which can be displayed either

directly on the instrument screen or on a connected computer for further

analysis and comparison to previous tests.

Features

- Operate as a stand-alone unit and via a computer

- Automatic and manual selection of water dosing

- Real-time display of ambient and chamber temperature & humidity

on touch screen - 7-inch capacitive touch screen controller to instantly set parameters

and monitor test status and results - Test data can be transmitted to the computer for real-time test curve

display with automatic report - Closed-loop control system (heated metal plate and air flow) secures

consistent test conditions - Accurate water volume determined by the built-in precision water pump

- Built-in high precision anemometer (air flow sensor) and infrared

thermocouple probe - Specialized software calculates the end time and drying rate R of each test

- Multiple test-curves overlay display for efficient comparisons of fabrics

Standards

- AATCC 201