Description

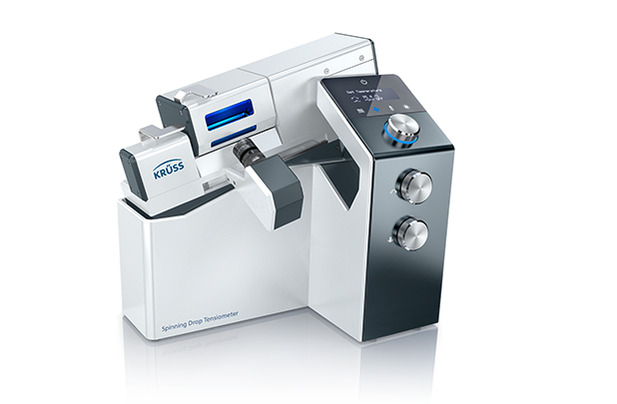

Spinning Drop Tensiometer – SDT

Measurement of interfacial tension in an extremely wide range with especially simple sample exchange

Our Spinning Drop Tensiometer – SDT measures interfacial tension with a high degree of accuracy and a particularly wide measuring range. The SDT is the ideal solution for the quality control and development of emulsions and surfactants thanks to its enormous bandwidth, small sample volumes and simple handling during preparation. Exact capture of extremely low interfacial tensions also makes the SDT an instrument particularly well-suited for analyzing the interfacial behavior of mini emulsions and micro emulsions, for example for tertiary oil recovery or the pharmaceutical branch.

Exact rotation and image evaluation

With the spinning drop method, measuring of the interfacial tension is carried out by analyzing the video image of a drop surrounded by fluid in a rotating capillary. The accuracy of the video analysis and the rotational speed are decisive for the precision of the spinning drop method. That is why a high-resolution USB3 camera and an exactly controlled precision motor with excellent speed constancy are among the most important components of the SDT, combined with the intelligent and robust image evaluation algorithms of the software ADVANCE.

In addition to the standard Vonnegut method, the ADVANCE software’s spectrum of methods also encompasses an evaluation of the drop shape in accordance with Young-Laplace. This makes it possible to work at a slower rotational speed and so expands the range of the instrument allowing easy measurement of high interfacial tensions. A further advantage of this method lies in its robustness.

Ergonomically designed, safety-ensuring housing

Completely novel in respect to the spinning drop technique is that all components, including the rotating capillary, are enclosed in a sturdy, closed housing. This virtually eliminates the risk of injury while the design with its clearly highlighted control elements makes working with the instrument very easy. The tilting and the camera position are motor-controlled while the camera itself is protected by a special recess that accommodates it in its park position.

Innovations for speedy sample preparation

One of the outstanding features of our SDT lies in the especially simple procedure for changing the samples. The novel concept for preparing the capillary, which has two patents filed by KRÜSS, significantly reduces the often laborious preparation otherwise involved in a spinning drop measurement. It also abolishes the need of regularly changing a septum which is normally required. The capillary is first filled with surrounding liquid while dismounted. Its specially shaped cap also serves as a holder for the drop liquid which enters the capillary when the cap is closed. With just one simple click the capillary is then placed in its holder.

Efficient and flexible temperature control

The speedy capillary changeover is achieved not least by the forgoing of a liquid temperature control, which at the same time saves the need for an additional thermostat. The integrated electric heater controls the target temperature quickly and accurately and is characterized by its high temperature stability. A cryostat can also be connected for analyses carried out at below room temperature. An accurate infrared sensor measures the temperature contactless and relays the thermal conditions very close to the drop.

Software with a new workflow-orientated operating concept

Our ADVANCE software focuses on simple automation and intuitive operability. The relevant functions for each particular step are arranged in tiles which display all elements necessary. By forgoing the use of menus and pop-ups, ADVANCE saves any unnecessary clicks and time-consuming searches for hidden elements.

Measuring with our Spinning Drop Tensiometer – SDT is completely software-controlled and uses prepared and easily adaptable procedures. ADVANCE automatically assigns every measured value to its associated drop image and presents it in the video tile. There is no need for the time-consuming saving, loading and management of image files.

Tasks and applications

- Development of emulsions

- Enhanced oil recovery (EOR)

- Bioavailability of drugs

- Surfactant research

- Adsorption properties at phase boundaries

Measuring methods and options

- Measurement of interfacial tension in a wide range starting from 10-6 mN/m

- Analysis using the drop diameter according to Vonnegut

- Analysis using the drop shape curvature according to Young-Laplace

- Long-term measurement for analyzing surfactant dynamics

- Temperature-dependent analyses